Did you know that there is a lucrative way to deal with the tons of wood materials waste produced by the manufacturing and constructions industry each year? You may have been wondering what can be done with the mountains of wood scraps and other organic waste that would otherwise end up rotting in a landfill. A wood charcoal making machine is the machine you need to produce profitable products from unusable wood.

This would be an especially profitable venture for those with an industrious mind and desire to make more money. A good connection with your source materials is the best place to start. The large quantities of wooden waste from manufacturing and construction projects creates a vast and never ending supply of waste products that can be turned to profit.

Wood charcoal is an important fuel source for many households. The charcoal and other by-products obtained from wood charcoal making machines have a variety of industrial and commercial uses. When done right, these machines take a useless waste material and transform them into an array of profitable products with high market value.

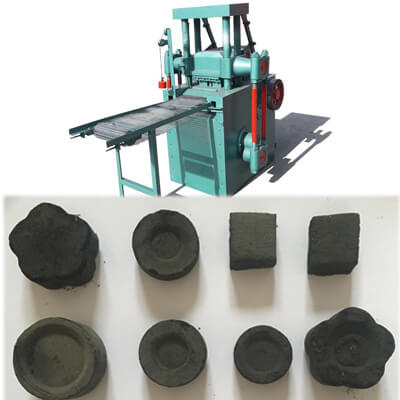

How A Wood Charcoal Machine Works

1. Carbonization

The first and most important step in the process is to increase the carbon content of the waste materials that you have placed inside. By improving the carbon content of the wood materials, the improved quality of your wood charcoals is improved. This will make cleaner burning and longer lasting fuel source for a wide variety of needs.

Whether you will be using rudimentary techniques learned over the ages or the efficiency of a modern wood charcoal making machine, the firsts step in the process is carbonization. This step in the process improves the carbon content of the wood steps used for charcoal.

2. Recycling Combustible Waste Gas

Next, the wood scraps will be subjected to the process of pyrolysis. Pyrolysis comes from a Latin term and means “transformation by fire.” Essentially, the wood burned in a low-oxygen environment ensures that the wood is chemically transformed into charcoal. During this process, other chemical compounds can be created as well.

The evaporation of resins and wood oils releases natural gasses. Some of these can be condensed in a condenser unit and re-used to fuel the wood charcoal making machine. Other gasses can be collected as wood spirits and wood vinegar that also has important uses in various industries.

Getting The Best Wood Charcoal Making Machine On The Market

If you are interested in fattening your bottom line while performing an important task that supplies industries with profitable products while simultaneously reducing the amount of waste materials being dumped on the planet.

Choosing The Best Wood Charcoal Making Machine

If you will be considering how the right biochar production equipment will fit your needs for profits and meet the demands, there are a few things to look for.

1. Eco-Friendly Options

The process of transforming wood into useful charcoal fuel is a trick as old as humanity. But, some of the outdated methods release heat, smoke, dust and fumes that can harm the environment in large quantities. This is why the most impressive machines have features that prevent heat exchange, collect fumes and dust and ensure that no harm comes to the environment.

2. Competitive Price

Take time to shop around for the option that best suits your demands and capacity. The most costly options are not always the best, you will need something tailor made to your exact needs.