Due to its high strength, high corrosion resistance and high wear resistance, brushed anodized aluminum is widely used in mechanical parts, aircraft and auto parts, precision instruments and radio equipment, architectural decoration, machine casings, lamps and lighting, consumer electronics, Household appliances, interior decoration, signage, furniture, car decoration and other industries.

galloping

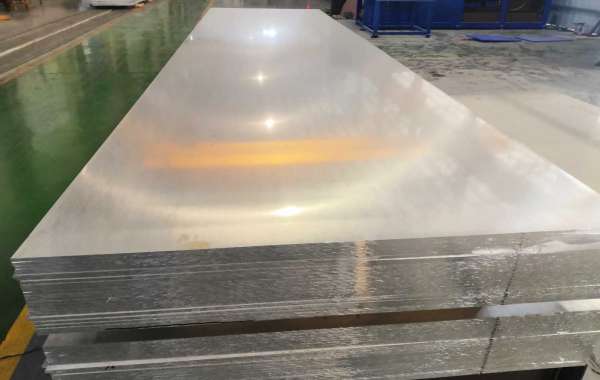

It is a surface treatment method that forms lines on the surface of 4x8 aluminum sheet by grinding, which has a decorative effect. According to the difference of the drawn lines, it can be divided into: straight line drawing, random pattern drawing, ripple pattern, swirl pattern. Because the surface drawing treatment can reflect the texture of metal materials, it has been favored by more and more users.

Anodizing

This is an electrolytic oxidation process. During this process, the aluminum alloy surface is often transformed into an oxide film that has protective, decorative and other functional properties.

Anodized aluminium or its alloys increase its hardness and wear resistance up to 250-500 kg/mm2. It also has good heat resistance, the melting point of the hard anodized film is as high as 2320K, and the insulation and impact resistance are excellent. It has better corrosion resistance and will not corrode for thousands of hours in ω=0.03NaCl salt spray.

Process flow of brushed anodized aluminum

Monochrome/Gradation: Polished/Sandblasted/Brushed - Degreasing - Anodizing - Neutralizing - Staining - Sealing - Drying

Two Colors: 1.0 Polished / Sandblasted / Brushed - Degreased - Masked - Anodized 1 - Anodized 2 - Sealed - Dry

Polished / Sandblasted / Brushed - Degreasing - Anodizing 1 - Laser Engraving - Anodizing 2 - Sealing - Drying

Technical Features:

1. This will greatly increase the strength.

2. It can achieve any color except white.

3. It realizes nickel-free sealing, which meets the requirements of Europe, the United States and other countries for nickel-free. Welcome to consult us for brushed aluminum sheet.